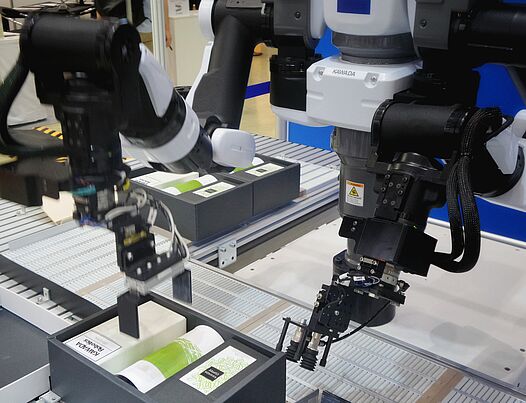

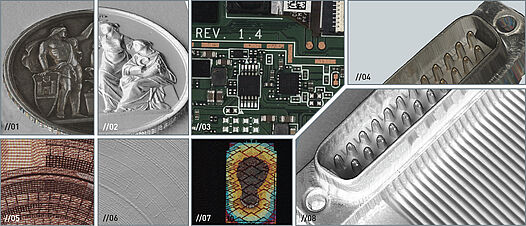

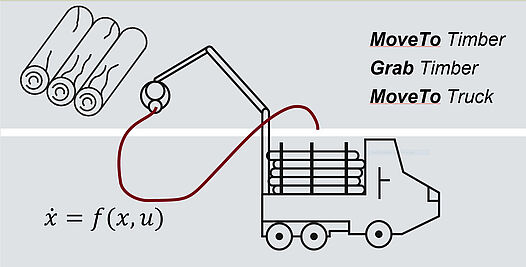

Artificial intelligence (AI) methods are being used in a variety of ways in production processes and in the development of autonomous machines and vehicles. At Berlin Science Week on November 7, AIT is hosting the high-profile event "AI-enabled Automation", which will discuss how intelligent machines can support humans and help solve major problems of the future, such as resource conservation, climate protection or labor shortages.