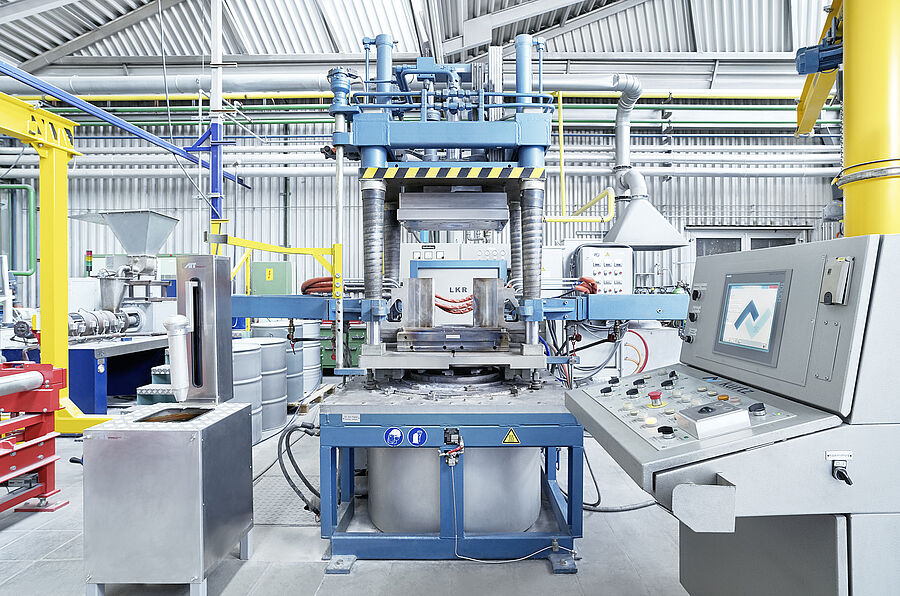

fully automated, semi-industrial experimental facility to develop complex components of Al and Mg alloys

Our services

- Process related and application-oriented light metal alloy development

- Mechanical property and thermodynamic property characterisation

- Metallographic examination and evaluation

- Component development/component simulation/component design

- Process development and process simulation

- Die development and tool testing

- Component sampling/Prototyping/pilot series

- Providing plant capacity (rental option)

- Holistic solutions from idea to series suitable component

Technical Data

| manufacturer |

| |

| casting unit |

| |

| crucible furnace |

| |

| cooling |

| |

| control unit |

| |

| peripherie |

|

![[Translate to English:] LKR Standort](/fileadmin/_processed_/2/8/csm_AIT_LKR_Standort_4fe61c1df0.jpg)